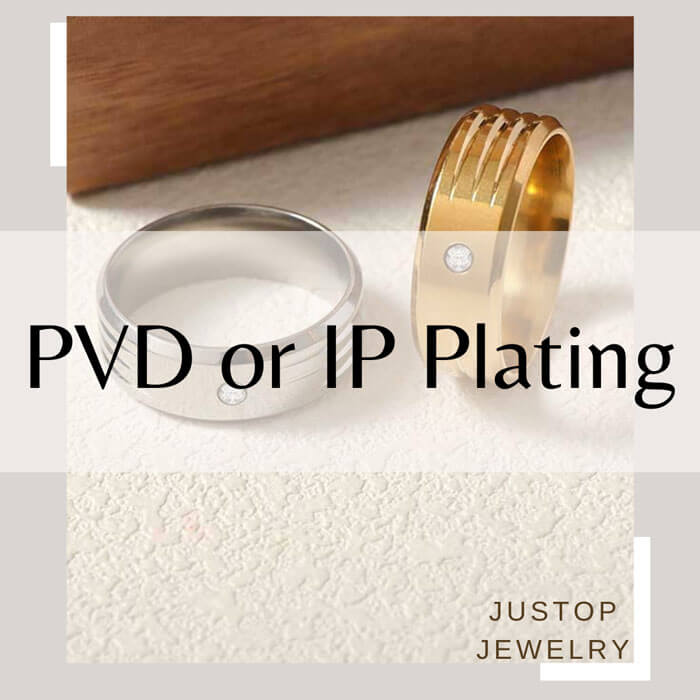

In the world of jewelry and watch manufacturing, plating technologies like PVD (Physical Vapor Deposition) and IP (Ion Plating) play crucial roles in enhancing the durability and aesthetics of metal products. Despite having different procedures and special advantages, these approaches are sometimes misunderstood because of their similarities. We’ll define PVD and IP plating, discuss their variations, and assist you in determining which plating technique could be most appropriate for your particular requirements in this extensive tutorial. Let’s explore these complex technologies’ layers.

What are PVD and IP Plating, and how do they differ?

PVD plating involves the vaporization of solid metal to a vapor that bonds on a molecular level with the target surface. IP plating, or Ion Plating, uses similar principles but involves ionizing the metal vapor before it reaches the surface, creating a more durable finish. Both methods extend the life of the jewelry but differ in application and durability.Curious about how these methods can enhance the beauty and longevity of your jewelry? Read on to learn more about these advanced plating technologies.

What Is PVD Plating?

Physical Vapor Deposition (PVD) is a coating process used extensively in the manufacturing of luxury watches and fine jewelry. The process involves:

- Vaporizing a metal into a plasma of ions.

- Bonding these ions onto the desired object at a molecular level.

- Producing a thin, hard coating that is exceptionally wear-resistant.

The result is a finish that can resist scratches and corrosion far better than traditional plating methods, making it ideal for pieces that endure heavy wear.

What Is IP Plating?

Ion Plating (IP) is considered an advancement in the PVD process, where the vaporized metal is ionized in a vacuum environment before being applied to the base material. This process includes:

- The use of a special bombarding process on the metal.

- The application of a durable and decorative coating.

- Creating a finish that is even more durable than standard PVD.

IP plating allows for a greater range of colors and finishes, making it a popular choice for fashion jewelry and other decorative items.

Differences Between IP and PVD Plating

While both PVD and IP plating offer enhanced durability and resistance compared to traditional plating techniques, they differ in their efficiency and the quality of the finish:

- Durability: IP plating generally provides a harder and more scratch-resistant finish.

- Color Range: IP plating offers a wider variety of colors due to the flexibility in the ionization process.

- Cost: PVD plating is often more cost-effective for larger batches, while IP plating can be costlier due to its complex process.

Common Applications of PVD and IP Plating

Both plating methods are used in various applications beyond jewelry, including:

- Watches: For enhanced aesthetic appeal and resistance to wear.

- Medical Devices: Due to their biocompatibility and durability.

- Automotive: For decorative trims and functional components that require longevity.

How to Care for PVD and IP Plated Jewelry

To ensure the longevity of your PVD or IP plated jewelry, follow these care tips:

- Avoid Chemical Exposure: Keep your jewelry away from harsh chemicals and cleaning agents.

- Clean Gently: Use a soft cloth and mild soap for cleaning.

- Proper Storage: Store your jewelry in a dry place away from direct sunlight.

Frequently Asked Questions About PVD and IP Plating

Is IP plating safe for sensitive skin?

Yes, IP plating is hypoallergenic, making it suitable for people with sensitive skin.

Can PVD or IP plated jewelry be repaired if damaged?

Repairs can be challenging, depending on the extent of the damage. It’s often better to replace the piece entirely.

How long does IP or PVD plating last?

With proper care, both types of plating can last for many years without significant wear.

Jewelry and other metal products can benefit from strong treatments to improve their durability and attractiveness, such as IP plating and PVD plating.

Whether you choose PVD for its cost-effectiveness or IP for its superior durability and color options, both methods provide significant benefits over traditional plating.

Interested in exploring PVD or IP plated products? Contact us or visit our website for more information and to view our extensive product range. We’re here to help you find the perfect, long-lasting jewelry solution that fits your style and needs.